What is a Waste Refinery?

A WR will be an industrial plant which will -

1 - Receive unsorted waste.

2 - The waste will be processed into small particles.

3 - Sort the waste particles into their component groups.

4 - At the same time as the particles are sorted, organic particles in the waste will be digested, and the resulting methane will used as fuel to generate heat and electricity.

5 - The sorted waste particles will be suitable material for re-cycling.

Therefore a WR will transform the waste stream into a source of energy and raw materials.

How will waste be processed into small particles?

A waste refinery will use conventional technology such as a waste shredder and a windhexe to process the waste in very small particles.

Video clip of a waste schredder.

Video clip of a windhexe.

How is a Waste Refinery different to conventional Alternative Waste Treatments?

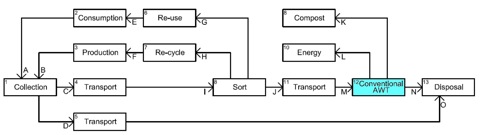

A waste refinery has a different function to the conventional alternative waste treatment (AWT) facilities. As our diagram 2020v1 shows, conventional AWT facilities are only a part of the whole waste process. (This diagram is based on the work of Sarah Mullin.)

Diagram 2020v1 showing that conventional AWT’s are only a part of the waste functional system.

Conventional AWT systems must still have the waste transported to a sorting facility, and then the sorting must take place. Some material can be extracted and re-used, however most waste needs considerable pre-processing before it is able to be used as basic raw material for a manufacturer. Typically after sorting waste needs to be washed and ground up before re-use. After sorting the waste is transported to a AWT where it is mostly used to manufacture compost, and sometimes to waste to energy plants. After the AWT, usually there is still some material that ends up in a landfill. AWT’s perform a very valuable function in the waste stream by minimising the amount of material that is landfilled. However, conventional AWT’s are only one part of the whole waste stream function.

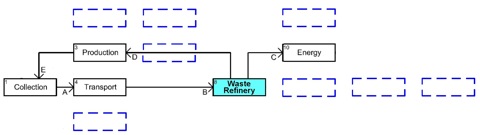

Diagram 2011v1 showing how a Waste Refinery simplifies the waste functional system.

A waste refinery will change the waste stream function by eliminating several of the functions that currently take place. Many transportation, compost and disposal functions are eliminated. Also there will only be 5 waste material transactions, instead of the previous 15 transactions. Also, a waste refinery will not require the waste to be sorted at source by the householder and this typically halves the waste collection costs. In addition, unlike recycled materials that typically need to be washed and granulated, the raw materials from a waste refinery will be delivered in format ready for production. Therefore a waste refinery will fundamentally change the waste industry.

Will it be difficult to process the waste into small particles?

Conventional waste shredding machines routinely grind up waste in an energy efficient way to particles sizes of about 20mm. (On inch is about 25mm.) Most waste is in the form of thin sheets of material, usually less than 1mm thick, so efficiently shredding waste into particles of 1mm or less should be achievable.

Will it be expensive to process the waste into small particles?

Shredding machines are in practice low cost machines to operate, however because a WR will require smaller particles than is usual, this will increase the cost of the process compared to a landfill situation. However in a re-cycling context, almost all products under go costly sorting, grinding up, cleaning and other processes before reuse. In the case of a WR, some of these processes are brought forward in a WR process. This means that the end products from a WR will able to be used at lower cost than other material sourced from the current waste steam. End products from a WR will be in the form of small particles, sorted and cleaned of impurities. Therefore this consistent product will command a higher price, and this high price will help offset processing costs.

Why not remove metals before processing?

Metals make up only a small part of the waste stream, about 8% or so. Also metals in the waste steam are usually in the form of thin sheets used to make cans and so on. In addition, when metals are re-cycled they are routinely reduced in particle size. So reducing metals to small particles should not be difficult. The reason for keeping the metals in the waste stream until the end is because metals, being highly chemically reactive, will break down complex chemicals like medicines, cleaning fluids and so on that are present in the waste stream. Also, metal powders are useful in many metal manufacturing processes such as sintering and so on. Therefore metals are not removed because they are beneficial in the WR process, and the powdered metals produced area a valuable raw material.

What about greenhouse gases such as carbon dioxide?

In a conventional landfill, biogas from the digestion of waste is released into the atmosphere. If the biogas from digestion is collected and burnt this reduces the greenhouse gas effect to about 4% compared to a conventional landfill. When burnt, methane plus oxygen reacts to produce carbon dioxide and water. Even though burning methane produces carbon dioxide, it is still best to burn it. This is because methane is a very powerful greenhouse gas, more than 20 times more powerful than carbon dioxide. Also when biogas is burnt, the carbon dioxide released will mainly be from the current carbon cycle, and not from fossil fuels. Therefore there should be reduced concern about this carbon dioxide release. In addition, the biogas from a methane digester or landfill usually contains from 25 to 50% carbon dioxide, this is mixed with a large amount of air so the methane can react with the oxygen in the air. Because of the carbon dioxide and large quantity of air, the gas that flows thru a conventional genset usually has a methane content of only about 5%. In a WR, there are two separate gas ports which will deliver methane and oxygen, which means that there is no carbon dioxide that will flow thru the genset, and so reduce greenhouse gas from this source. Also, because of the oxygen from the oxygen port, this means that only a small amount of air from the atmosphere will be needed. Having no carbon dioxide, and a high oxygen content, means that the methane content of the gas that flows thru a WR genset will be nearly doubled, to about 9%. This means that a WR genset will be more efficient, and will be able to generate more heat and electricity for a given amount of methane than a conventional biogas genset. Therefore, when greenhouse gases are considered, a WR has an very large advantage over conventional landfills, and a smaller but still significant advantage over conventional methane digesters.

What will be the major sources of income?

A WR will have 3 main sources of revenue -

1 - Waste acceptance or dump fees

2 - Energy sales

3 - Raw material sales

How much will a WR cost to build?

We currently expect that a plant will cost about $250 per person. This makes it about the same cost as conventional waste management systems. Obviously there will be some scale factors, for example a smaller plant is likely to cost more per head than a larger plant.

How much will a WR cost to operate?

We currently expect that a WR will be able to fund it’s operating costs, and also provide a utility rate of return on the investment in the plant. Because a WR will bring forward the usual recycling costs it will be relatively expensive, however because the end products will be more refined, the end products will generate larger revenues. Also it will produce about 10% of the electrical energy needs of the population served.